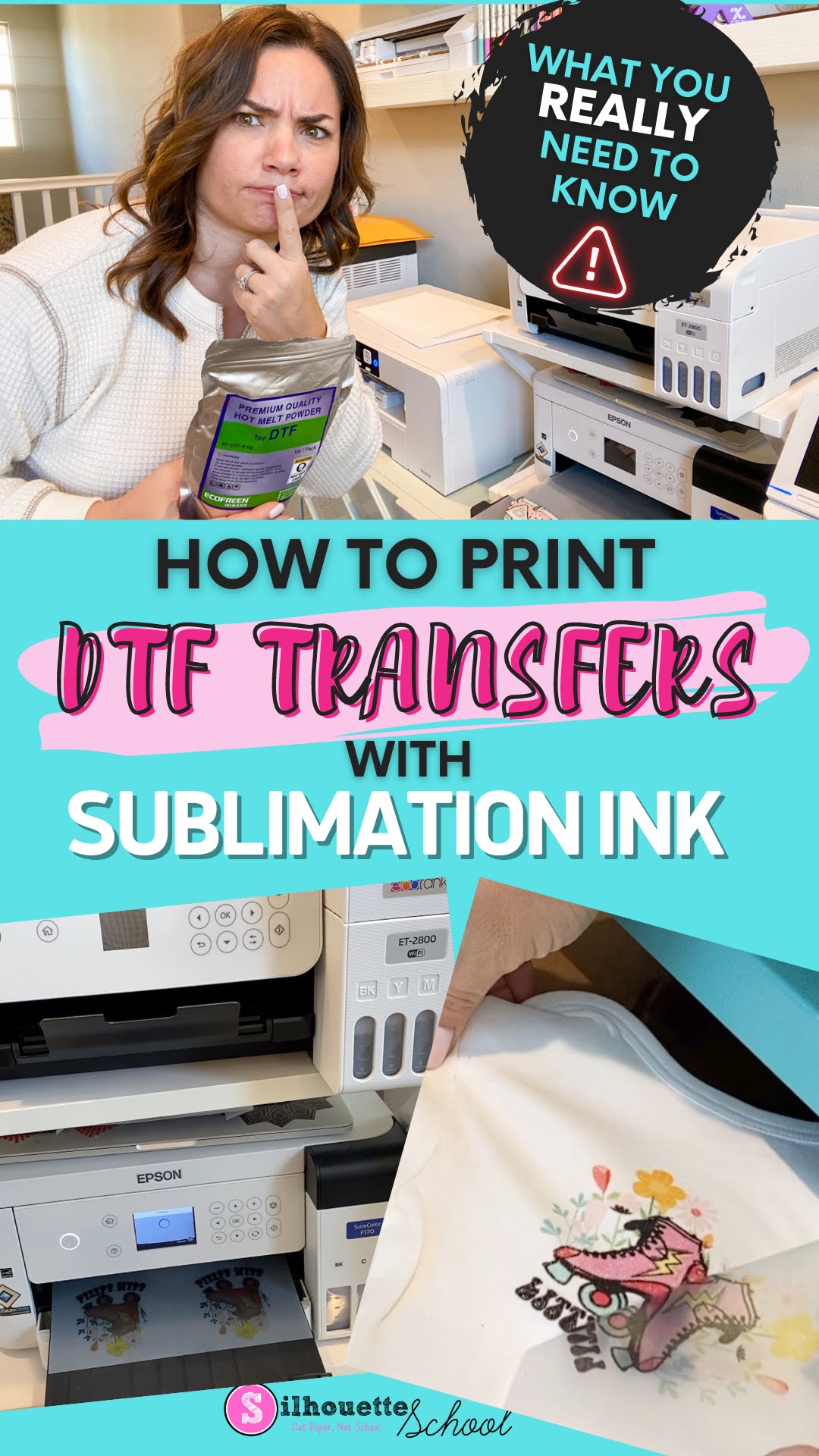

How to Make DTF Transfers with Sublimation Printer

Want to learn How to Make DTF Transfers with Sublimation Printer? This innovative technique allows you to customize textiles easily and efficiently, combining the best of sublimation and DTF. In this article, we’ll guide you step-by-step so you can take advantage of your sublimation printer to create vibrant and long-lasting designs. If you’re looking to expand your textile printing options, this is the perfect process to start!

What is DTF Transfers

DTF transfers (Direct-to-Film transfers) are a method of printing designs onto a special film and then transferring those designs onto fabrics using heat and pressure.

What is Sublimation Printer

A sublimation printer is a special type of printer that uses heat to transfer dye onto materials like fabric, metal, plastic, or ceramic.Sublimation doesn’t work well on 100% cotton or dark fabrics unless special coatings are used.

How to make dtf transfers with sublimation printer

Normally, you can’t directly make DTF transfers with a regular sublimation printer because sublimation printers and DTF printers use different types of ink and printing methods.

However, it is possible if you convert a sublimation printer (especially Epson models) by doing the following:

- Clean the Printer Thoroughly:

Remove all sublimation ink and clean the lines and printhead completely to avoid contamination. - Fill with DTF Ink:

Replace sublimation ink with special DTF water-based pigment inks (CMYK + White). Sublimation ink will not work for DTF. - Use DTF Film:

Instead of sublimation paper, you print your design onto PET DTF film. - Apply Adhesive Powder:

While the print is still wet, sprinkle DTF hot melt powder over the design and shake off the excess. - Cure the Design:

Cure the powder using a heat press (hover method) or a curing oven until the powder melts and becomes glossy. - Heat Press the Transfer:

Press the DTF film onto your fabric using a heat press at 300–320°F (150–160°C) for 15–20 seconds. - Peel and Finish:

Let it cool down slightly, peel off the film, and optionally do a second press for a softer finish.

Important notes:

- You need special DTF ink and DTF PET film — sublimation supplies won’t work.

- Sublimation printers do not print white ink, so you’ll need to work around that if your design requires a white base (limiting your printing on dark fabrics).

- It’s better to start with a printer that’s designed for DTF if you want the best results.

Post Comment